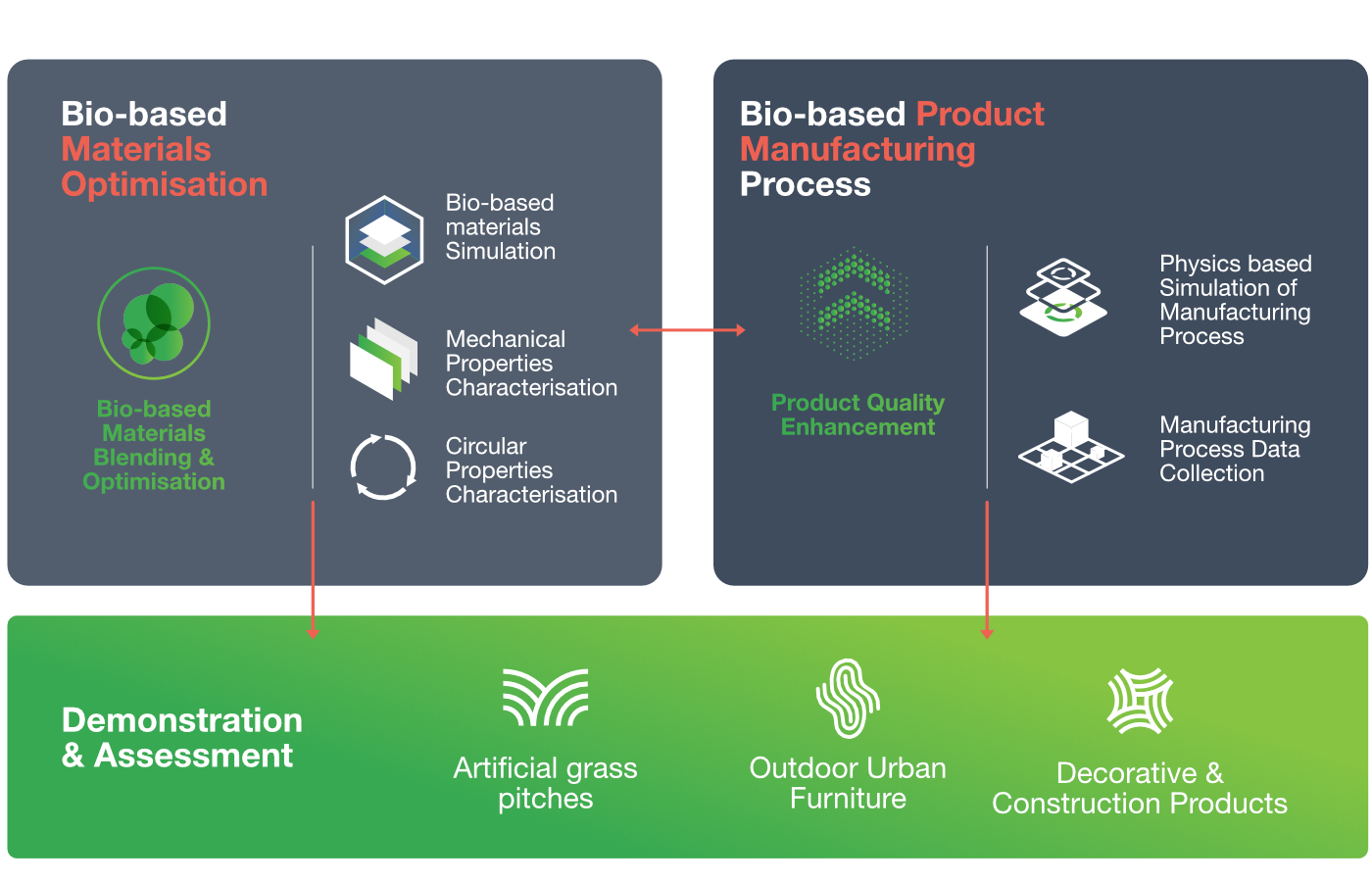

Technology

A mix of experimental activities and digital approaches will be used to improve bio-based composite materials and manufacturing processes and create a life cycle model of each manufacturing value chain.

This model will provide useful information for the design of the bio-based product and facilitate its further refurbishment and remanufacturing. Simultaneously, it will assist the optimisation of manufacturing processes with feedback on materials, machine, and process parameters.

By utilising novel digital-based circularity concepts, AMBIANCE will extend the life cycle of bio-based products and increase their robustness against environmental and production changes.

Novel bio-based

materials

The development and optimisation will be achieved, following 2 alternative courses:

By processing agricultural side streams to create innovative self-bonded bio-based material.

1

By using modifiers to enhance material properties. Different experiment designs will allow to assert the optimum formulation of the material. At the same time, simulation and data analysis will attribute in the assessment and optimisation of the material’s characteristics.

2

Material

Characterisation

Design of Experiments (DoE) – To achieve the required material properties, countless experiments must be carried out with all possible parameters affecting the mechanical properties of the material. For that reason, experiments will be combined with statistical techniques in a Design of Experiment approach, to accelerate the production of results.

Molecular Dynamics (MD) – This simulation tool will be used to predict the biobased material properties and the mechanical and thermal properties of the biobased composite materials.

Material Optimisation Techniques

To ensure product compliance, AMBIANCE will proceed with extensive material characterisation, conditioned by existing standards and requirements covering both the physicochemical and mechanical aspects.

A biodegradability characterisation will be carried out too since the novel materials strongly rely on biomass.

Recyclability

Characterisation

AMBIANCE will investigate how the material's final properties are affected by the recycling process and how to improve them utilising fillers, modifiers, and compatibilisers.

The number of recycling cycles that the new bio-based materials can tolerate will be determined using thermal analysis such as DSC (differential scanning calorimeter), TGA (thermo gravimetric analysis), rheology, or viscosimetry.

Manufacturing

Processes

Because of their properties, bio-based materials demand innovative and adaptable manufacturing processes, responsive to the characteristics of the feedstock in each manufacturing stage as well as to the end-product requirements. In this respect, it is necessary to modify current characterisation techniques and quality control systems to account for the unique physical and chemical properties of the novel materials.

To respond to the process optimisation needs, AMBIANCE will employ several advanced digital technologies, both for data acquisition as well as simulation models.

AMBIANCE will elaborate on the following manufacturing processes:

Filament extrusion

FPF LSAM

Compression Moulding