Use Cases

The solutions developed within the spec of AMBIANCE, will be showcased, and integrated in three demonstration sites.

Use Case 1

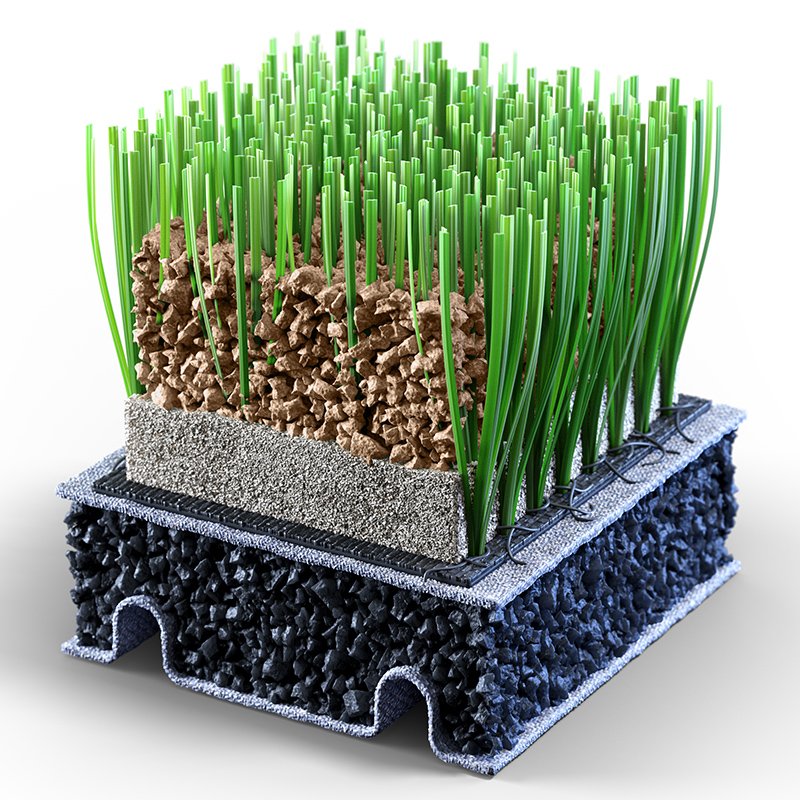

Sports Facilities

Artificial turf has a significant environmental impact due to its tactical renewal and the difficulty of its recycling. The priority of Mondo is to reduce the impact in the lifecycle of such products, by using bio-based materials which are recyclable, compostable or can offer recirculation alternatives.

This use case will deal with the different manufacturing processes of artificial grass pitches in sport facilities. The operations will cover the filament extrusion and the infill pellet mixing as well as the whole production process in an effort to optimise the manufacturing parameters.

To that end a hybrid digital twin will be deployed combining both physics-based reduced order models and data driven approaches.

The benefits

Enhance the material properties for lower abrasion, better durability, and higher performance.

Reduce the production costs.

Lower the environmental impact of such products.

Outdoor Furniture

Use Case 2

This demonstrator will focus on large-scale manufacturing of 3d printed outdoor furniture using recycled materials.

The aim of Setga is to test the feasibility of such large-scale 3d printing production, using recyclable biobased polymers optimised with additives for higher performance. The end products should be able to endure any weather conditions and human-related factors as well as feature an attractive design responding to various end-user needs.

The manufacturing facility for this use case consists of an LSAM (Large Scale Additive Manufacturing) robot cell. Real time temperature 3D mapping generation through a thermographic camera, to assist the printing process, will be developed and embedded in the robot cell.

The Benefits

Better endurance of materials against climate and human factors.

Better recyclability and biodegradability properties.

Reduce of lifecycle costs.

Construction Bricks and Decorative Panels

Use Case 3

This use case will work on the manufacturing of bio-based construction bricks and decorative panels composed solely of agricultural side streams.

Rise Sicomp and Podcomp will research on processing certain agricultural side streams to obtain durable composite materials, while optimising their manufacturing process. At the same time, the new bio-based material will decrease the environmental impact by maintaining high reusability, high recyclability, and low waste production.

The production system will be retrofitted with customised Fibre Optic Sensors and Terahertz imaging to monitor the thermoforming process embedded in the mould and manage the information accordingly to adapt and improve the process for the new bio-based materials.

The Benefits

Lower environmental impact.

Lower waste during the material processing.

Increased recyclability and reusability.